High Performance & Engineering Plastics

Our diverse product portfolio provides Engineers with many sealing options depending on the environment, size, and quantity due to our expertise in polymer science.

Learn more about how plastics can improve your operation today.

Contact Us Top -Plastics for Engineering

We will get back to you as soon as possible

Please try again later

Material Selection

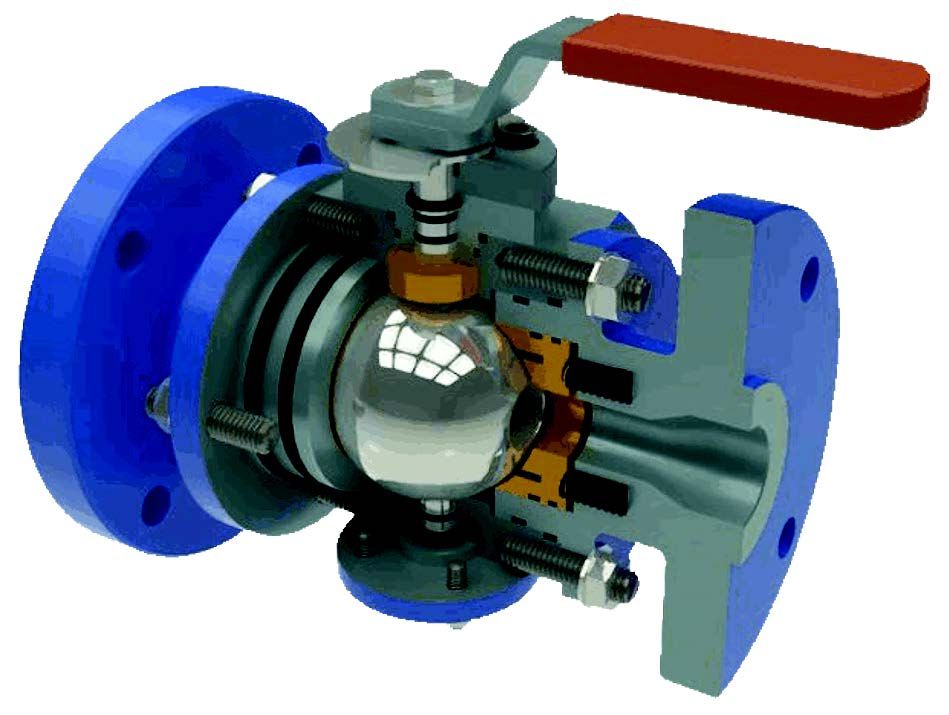

Choosing the suitable material for your Valve sealing applications can be challenging. Demands for performance at Increased temperatures, Higher pressures, and long-term exposure to corrosive media create new challenges for seal manufacturers. With so many material options choosing the best material(s) for effective sealing solutions can be overwhelming. Laird Plastics can help navigate you when extreme conditions are a factor.

Extreme conditions require extreme materials and a supplier who understands polymers science. Laird Plastics can help navigate the features and benefits engineered polymers provide. Our diverse product portfolio offers engineers many sealing options suitable for their application environment.

Typical Applications

- Rotary Shaft Seals

- Valve Seals

- High wear components

- Start-Stop Applications

- Corrosive Seals

- Pumps and Compressors

Laird Plastics is a Global leader for stock shapes, near net parts, and machined components. We work with the world's best material manufacturers who have designated focus in the sealing industry.

Temperature and pressure can promote leakage in valves. Laird plastics understands the importance of choosing the right polymer for your sealing solutions. A small increase in temperature or pressure can contribute to a leaky valve.

Eliminate the Void

Spun Molding process is an underused method to produce relatively large yet thin-walled tubes and rings from high performance polymers such as PEEK. Unlike extrusions, compression molding, or injection molding, spun casting is very flexible regarding wall thickness and production. Lead times tend to be much shorter than traditional processes used to produce tubes. Quality, Performance, and MOO (Minimum Order Quantity) are three significant benefits of Spun Cast Technology.

Our diverse product portfolio provides Engineers with many sealing options depending on the environment, size, and quantity due to our expertise in polymer science.

Benefits of the Spun Cast Material Portfolio

- MOO can be one piece Low Internal Stress

- ID / OD Concentricity No porosity / No knit lines

- Size 1 OOMM to 500MM

- Increased ductility when compared to Injection Molding

- Norsok M-170

Typical Applications

- Split Rings

- Stem Seals

- Back up Rings

- Pumps and Compressors

- Valve Seals

- Corrosive Seals

- Rider Bands

Plastic Materials

Röchling LubX® CV

Valves can become sticky depending on the media flowing through them. Rochlings LubX® CV is a Low

COF sliding material developed for systems intended to perform with fast actuation and higher pressure loading. Eliminate Sticky Valve Seals and increase your productivity using LubX® CV. Scientific research shows using LubX® CV can significantly improve system performance and efficiency. Even when used for high-load applications, it retains its excellent sliding characteristics and high wear resistance.

Extreme conditions require extreme materials and a supplier who understands polymers science. Our

diverse product portfolio provides Engineers with many sealing options depending on the environment, size, and quantity.

Benefits of Lubx® CV

- Excellent sliding properties even at higher velocities and PSI Load

- Excellent dry-running properties

- Reduced energy consumption

- Longer maintenance intervals

- Less stress on actuators

- High wear resistance

- Food Compliance according to 10/2011/EU, 1935/2004/EC, FDA

- Visually Detectable Blue

Typical Applications

- Scroll Seal

- Valve Seals

- Cyrogenic Seal

- Food Valves

- Stem Seals

- Corrosive Seals

- Gasket

- Pumps and Compressors

Ketron® CM

Ketron® CM 1030HT Polyetherketone PEK provides added stiffness at high temperature, Carbon filled for added strength and stiffness, Good dimensional stability, and Excellent chemical and corrosion resistance.

- Isotropic material properties

- High Temp Seal applications Above 400F

- Heat Deflection Temp 450F

- Excellent Wear Properties in dynamic seal applications

Typical Applications

- Rotary Shaft Seals

- Isolator Bearings

- Valve Seals

- Rod Seal

- Lantern Rings

- Pumps and Compressors

Contact Us

Learn more about how plastics can improve your operation today.

Unit #2-3, 5367 271st Street

Langley, BC V4W 3Y7

Phone: 604-888-8331

Toll Free:

800-663-4484

Email:

vancouver@lairdplastics.com

Plastics for Engineering

We will get back to you as soon as possible

Please try again later

All Rights Reserved | Laird Plastics Vancouver